Inventory count with Drone

Inventory of physical stock in storage locations using the drone

Usually checking of products status and the counting of products is done manually and for counting the products from shelves is necessary to use a nacella lifleted by a forklift in order the operator to see and count the products.

We are proposing a revolutionary solution and a faster one, like scanning the pallets from storage with a Drone.

The Drone raises a barcode scanner to the high shelves and methodically moves down or sideways on the lanes between rows by scanning the barcodes from the pallets, meanwhile the operator receives the direct feedback.

A live video stream allows the operator to inspect the status of the products or check the contents of the pallets. Photo and video images can then be associated with the scanned items in the offline viewing database.

Checking the status of a product or its content is usually done manually. Aptus DroneScan offers a way to do this quickly and efficiently because the drone is equipped with a camera. Aptus DroneScan allows you to take photos for further processing, or a live video stream for live viewing in the pilot control module.

Photos and video footage can be uploaded to the server for later retrieval and reporting purposes.

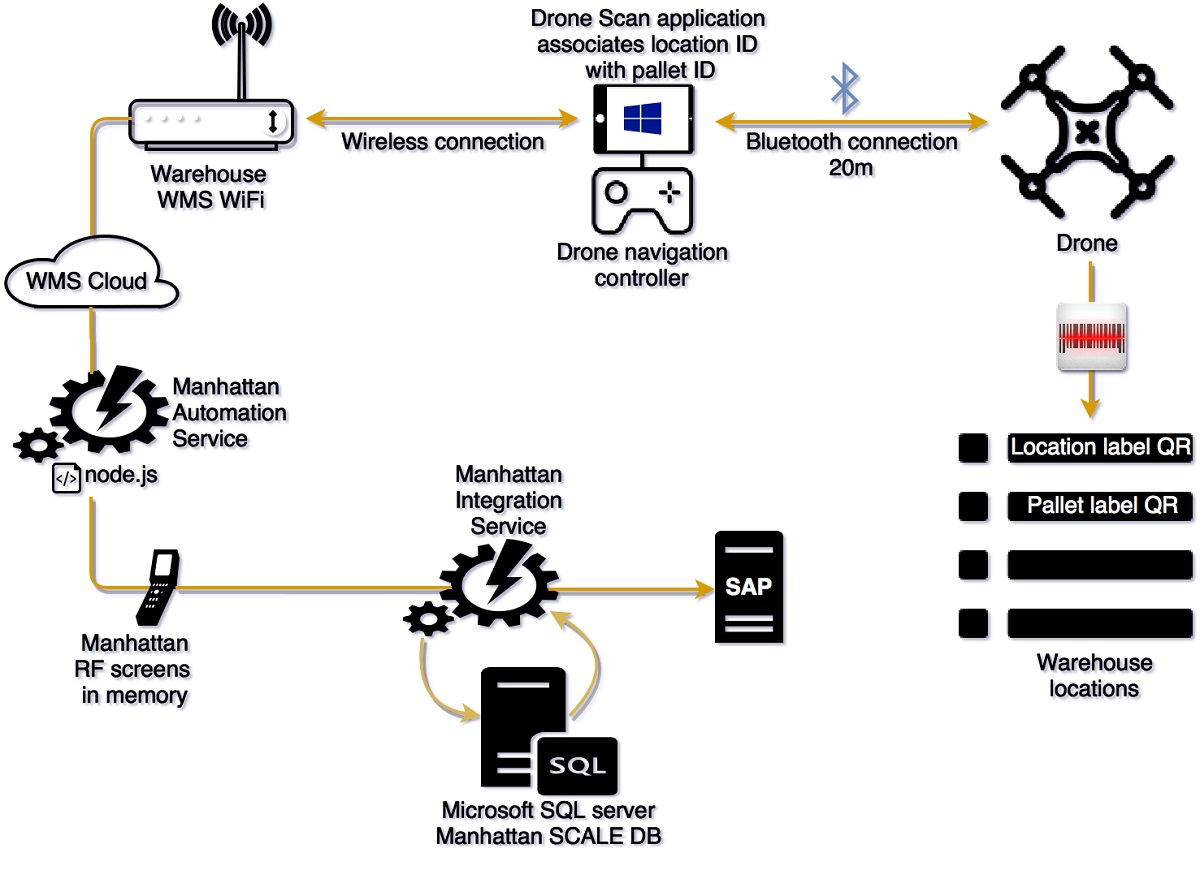

The simplicity of the Aptus DroneScan system involves low costs with the infrastructure required to inventory a warehouse. The only requirement is to upload a file with the warehouse stock to the Aptus DroneScan database, and to prepare the drone with the associated scanner. After or during scanning, reports and files can be generated and sent directly to the back office or uploaded directly to WMS- warehouse mnagement system.

The Aptus DroneScan system is portable, which can be used in different warehouses. The drone and inventory accessories can be ready for work in 10 minutes and packaged in 5 minutes for moving to another location. It comes with a sturdy travel case and can be carried in the baggage hold of any airline.

Some warehouses have location codes placed directly on pallet bars, in which case, the drone can scan these codes and use them to improve the accuracy of position estimation.

Example of Cycle counting process

The cycle counting operation is mostly used when stock inventories take place. This allows the use of all end users in the process of counting locations defined in the system.

The procedure consists of creating a series of tasks for inventorying the locations, which are immediately available to the warehouse users. There is the option to create counting work only on certain areas defined in the warehouse so that partial inventory can be executed also. Tasks created by the WMS system following a cycle counting can be taken over by an enduser who will follow the steps indicated by the RF gun. The system will send the user to number each marked location for back office counting.

In the picture below is designed the process of counting, via the drone, for the pallets from storage locations inside the warehouse.

Due to the fact that probably more than 75% of the products are being stored in upper shelves in most warehouses, by using Drone for counting the inventory, the time allocated for this activity will decrease considerably, also the number of personnel dedicated to this activity.