In the fast-paced world of operational logistics, maintaining efficiency, consistency, and accuracy is crucial. These principles ensure that the supply chain operates smoothly, meeting customer demands and maintaining a competitive edge. At the heart of achieving these objectives are Standard Operating Procedures (SOPs). SOPs are comprehensive, written instructions designed to achieve uniformity in the performance of specific functions, providing a roadmap for employees to follow.

Enhancing Efficiency and Reducing Errors

One of the primary benefits of SOPs is their role in enhancing efficiency. By providing clear, step-by-step guidelines, SOPs eliminate ambiguity and reduce the time employees spend figuring out what to do. This streamlining effect is particularly important in logistics, where time is often of the essence. For instance, in a warehouse setting, SOPs can standardize processes such as inventory management, order picking, and packing, ensuring that these tasks are completed quickly and accurately.

Moreover, SOPs play a crucial role in minimizing errors. In logistics, mistakes can be costly, leading to delays, damaged goods, and dissatisfied customers. SOPs mitigate these risks by ensuring that every task is performed correctly and consistently. By following standardized procedures, employees are less likely to overlook critical steps or deviate from established best practices.

This video humorously 🙂 highlights how lack of clear instructions can lead to chaos, which is a great analogy for why SOPs are essential in logistics. Just as the dad in the video struggle with vague directions, logistics operations can suffer without precise SOPs.

Facilitating Training and Onboarding

SOPs are invaluable tools for training new employees. They provide a comprehensive guide to performing various tasks, making it easier for newcomers to learn the ropes. This is particularly important in logistics, where high turnover rates and seasonal fluctuations can result in a constant influx of new hires. With well-documented SOPs, new employees can quickly get up to speed, reducing the learning curve and increasing productivity.

Furthermore, SOPs serve as a reference point for existing employees, ensuring that knowledge is retained within the organization even as staff members come and go. This continuity is vital for maintaining operational stability and ensuring that best practices are preserved.

Ensuring Compliance and Quality Control

In many industries, logistics operations are subject to regulatory requirements and quality standards. SOPs help ensure compliance with these regulations by documenting the correct procedures for handling, storing, and transporting goods. By following SOPs, companies can demonstrate their adherence to legal and industry standards, reducing the risk of fines, sanctions, and reputational damage.

Additionally, SOPs support quality control initiatives by standardizing processes and establishing benchmarks for performance. By monitoring adherence to SOPs, managers can identify areas for improvement, implement corrective actions, and ensure that operations consistently meet quality expectations.

Promoting Safety and Reducing Risk

Safety is a critical concern in logistics, where the handling of heavy machinery, hazardous materials, and complex processes can pose significant risks. SOPs play a vital role in promoting safety by providing detailed instructions on how to perform tasks safely. This includes the proper use of equipment, the correct handling of hazardous substances, and the implementation of emergency procedures.

By following SOPs, employees can reduce the likelihood of accidents and injuries, creating a safer work environment. Moreover, SOPs help ensure that safety protocols are consistently followed, which is essential for maintaining compliance with occupational health and safety regulations.

Enhancing Communication and Collaboration

Effective communication is essential in logistics, where coordination between different teams and departments is crucial for smooth operations. SOPs enhance communication by providing a clear and consistent framework for performing tasks. This ensures that everyone is on the same page, reducing misunderstandings and improving collaboration.

For example, SOPs can outline the process for receiving and dispatching goods, ensuring that warehouse staff and transportation teams work together seamlessly. By fostering better communication and collaboration, SOPs help create a more cohesive and efficient logistics operation.

Adapting to Change and Continuous Improvement

The logistics industry is constantly evolving, with new technologies, regulations, and market demands shaping the way operations are conducted. SOPs provide a flexible framework that can be adapted to accommodate these changes. By regularly reviewing and updating SOPs, organizations can ensure that their procedures remain relevant and effective.

Furthermore, SOPs support continuous improvement initiatives by providing a baseline for evaluating performance. By analyzing adherence to SOPs and identifying areas for improvement, organizations can implement changes that enhance efficiency and effectiveness. This iterative process of reviewing and refining SOPs helps organizations stay competitive in a dynamic industry.

Supporting Strategic Planning and Decision Making

SOPs are not just operational tools; they also support strategic planning and decision-making. By providing detailed documentation of processes, SOPs offer valuable insights into how operations are conducted. This information can be used to identify strengths and weaknesses, assess risks, and make informed decisions.

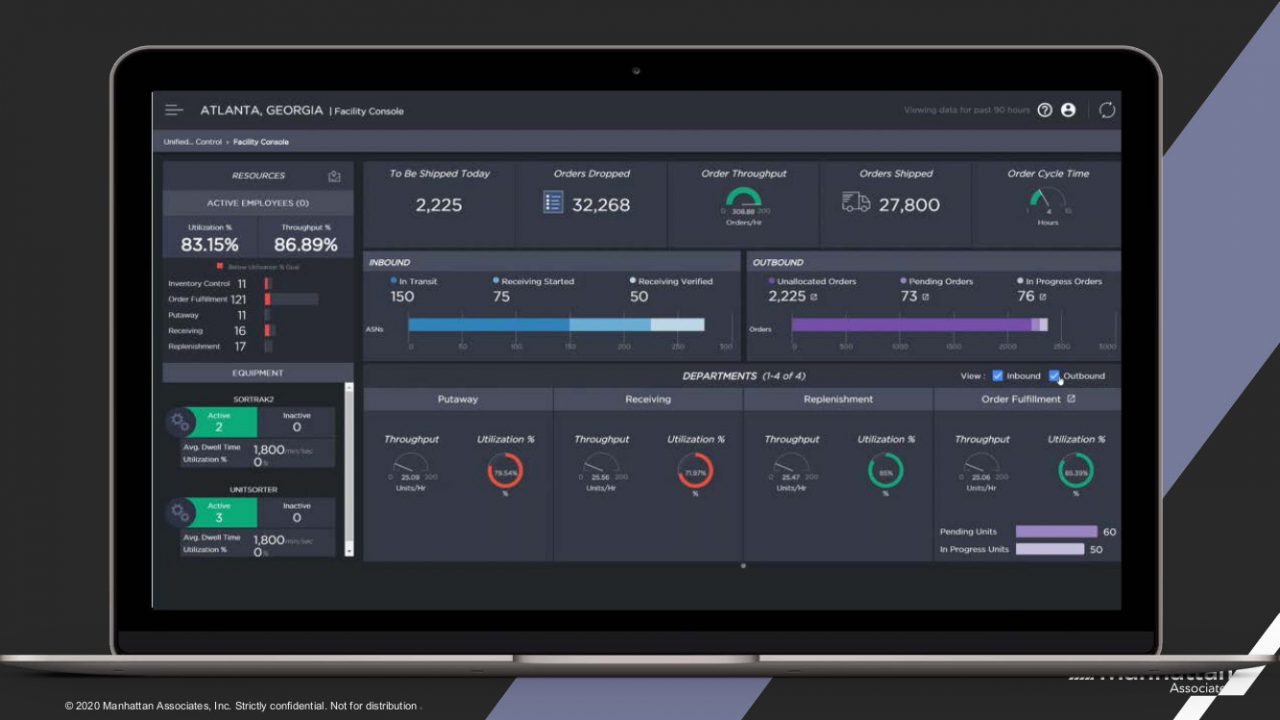

For instance, SOPs can help logistics managers analyze the efficiency of different procedures, the effectiveness of inventory management strategies, and the impact of various factors on task completing times. By leveraging this information, organizations can develop more effective strategies and make data-driven decisions that enhance their overall performance.

Building a Culture of Accountability and Ownership

Implementing SOPs fosters a culture of accountability and ownership within an organization. By clearly defining roles, responsibilities, and procedures, SOPs ensure that employees understand what is expected of them. This clarity promotes accountability, as employees are aware of the standards they need to meet and the procedures they need to follow.

Moreover, SOPs empower employees by providing them with the based knowledge and tools they need to perform their tasks effectively. This sense of ownership enhances job satisfaction and motivates employees to take pride in their work. As a result, organizations with well-implemented SOPs often experience higher levels of employee engagement and productivity.

Conclusion

In conclusion, Standard Operating Procedures (SOPs) are essential components of operational logistics. They enhance efficiency, reduce errors, facilitate training, ensure compliance, promote safety, and support quality control. Additionally, SOPs enhance communication, support strategic planning, foster accountability, and enable continuous improvement. By providing clear, standardized procedures, SOPs enable logistics operations to run smoothly and effectively, contributing to the overall success of the supply chain. As such, organizations that invest in developing and maintaining robust SOPs are better positioned to achieve operational excellence and meet the demands of their customers.

The above video humorously illustrates the chaos that can ensue without clear guidelines, akin to the importance of SOPs in logistics. Just as the video shows the need for specific instructions to avoid confusion, SOPs provide the necessary clarity and direction to ensure efficient and error-free logistics operations.

In a world where logistics operations are becoming increasingly complex and competitive, SOPs offer a reliable foundation for achieving consistency, efficiency, and excellence. Whether you are managing a small warehouse or overseeing a global supply chain, the importance of SOPs cannot be overstated. They are the blueprint for operational success, guiding employees and ensuring that every aspect of the logistics process is performed to the highest standard.